obvioTec Foreign Particle Detector

Development Platform

Explore how higher frequency THz waves (>300 GHz) can be used to detect small defects embedded within solid matrices such as lyocakes, crucial components in pharmaceutical manufacturing. Employed in a transmission geometry with a tightly focused THz beam, our innovative approach facilitates penetration through primary packaging (e.g., glass vials). The contrast in the resulting images, derived from transmission losses due to defect presence, underscores the effectiveness of our system's design. This achievement is made possible by advanced data analysis techniques, integral to processing collected information for precise defect identification and characterization within the solid matrices.

Pros

-

Penetration: Traversing paper, plastic, and carton poses no obstacle, yet encountering substantial

losses with glass, THz waves demonstrate the capability to penetrate glass vials.

-

Safe Imaging: Similar to GHz waves, THz waves are non-ionizing, prioritizing safety without compromising

performance.

-

Improved Resolution: Increased resolution (<1mm) compared to GHz waves.

Cons

-

Depth Limitation: While powerful, THz waves offer less penetration depth compared to GHz

waves.

-

Scan Methodology: Presently, the system requires a point-by-point scan approach, optimizing detection limit at the

expense of speed.

Case Study: Foreign Particle Detection Inside Lyocakes

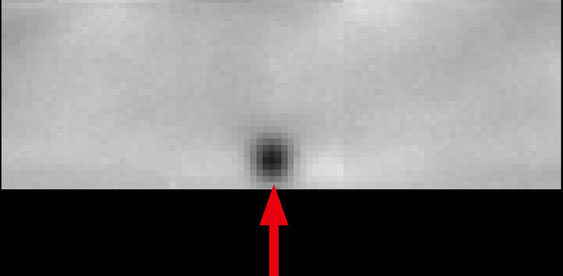

Detecting defects within the solid matrix of lyocakes presents a formidable challenge due to their opaque nature, rendering conventional inspection methods inadequate. Presently, visual inspections conducted by humans can only identify defects on the outer surface of lyocakes. We revolutionize this process by penetrating the opaque lyocake and detecting foreign particles, such as glass particles, with remarkable precision. Capable of detecting particles as small as 1 mm (in diameter) deep inside lyocakes, we offer unparalleled insight into product quality and safety. The accompanying illustrated image demonstrates the detection of a spherical defect nestled at the bottom of a vial, showcasing the technical prowess and effectiveness of our THz solution in enhancing quality control measures.

1 mm diameter glass bead inside a D-Mannitol based lyocake (prepared in-house). The glass bead is located at the bottom of the vial.

lyocake matrix

Corresponding THz image of the sample (~ 8000 pixels)

1 mm glass bead

obvioTec AG | Sonnenbergstrasse 74 | 8603 Schwerzenbach | Switzerland

044 515 55 33 | welcome@obviotec.com | www.obviotec.com

| bg-primary | |

| bg-primary-light | |

| bg-primary-dark | |

| bg-secondary | |

| bg-secondary-dark |

| body | |

| top-header | |

| header | |

| content |

| background | |

| text color | |

| link color | |

| horizontal line |

| style 1 | |

| style 2 | |

| style 3 |

| social icons | |

| navigation color | |

| subnav background |

| background color | |

| navigation color |

| has-right-nav g-font |

| size-15 weight-400 snip-nav |

| form-white |

| o-form color-white |

Note: All changes made here will be applied to your entire website.